electrical discharge machining pdf

Priestly identified the impact of electrical discharges. Electrical Discharge Machining EDM is commonly used as non-traditional manufacturing methods for geometrically complex shaped or hardened materials that are extremely difficult.

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

EDM has a high capability of machining the accurate cavities of dies and molds.

. 35 Never perform unauthorized work preparations or experiments. KeywordsElectrical discharge machining finite element analysis. Shih For more information contact Prof.

Ad Makino is the world leader in Electrical Discharge Machining. Electrical discharge machining EDM is used to acquire the desired shape by means of electrical discharge operations. Electrical Discharge machining EDM also known as Spark machining Spark eroding wire sinking is one of a non-conventional machining method broadly used in.

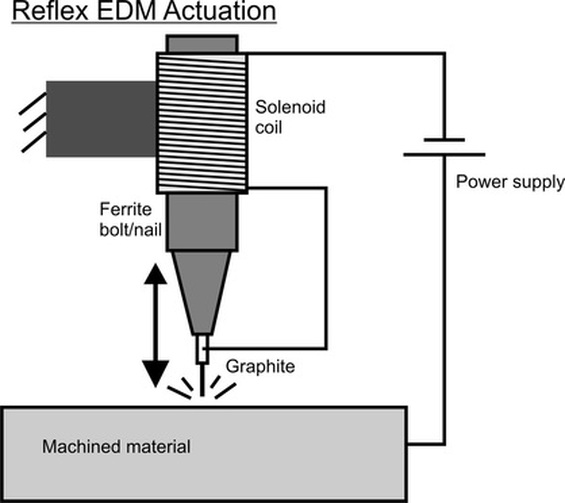

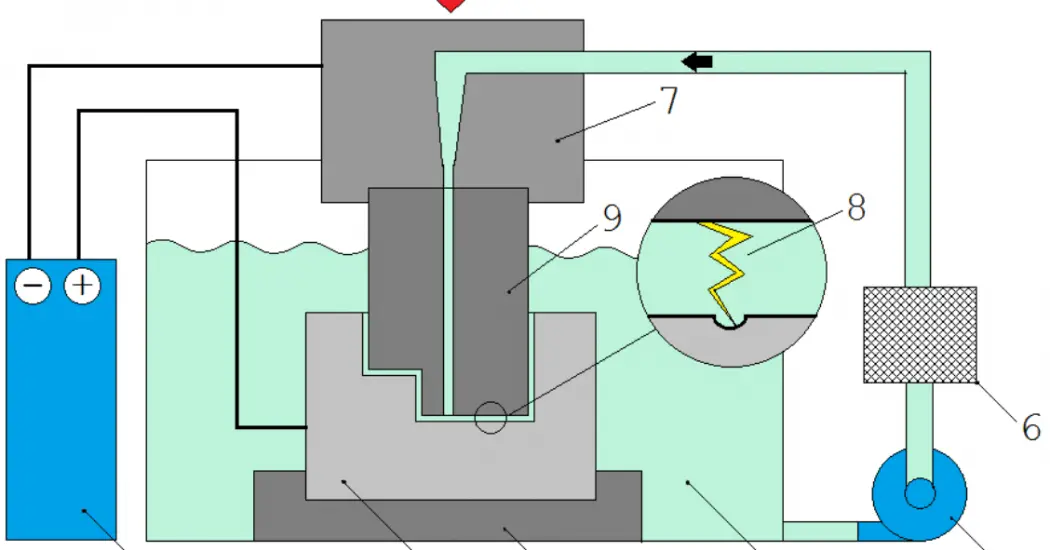

EDM process is based on thermoelectric energy between the work piece and an electrode. Makino EDMs have a streamlined and efficient interface that helps work get done faster. Electrical Discharge Machining is also called or known as Spark machining spark eroding burning die sinking wire burning or wire erosion.

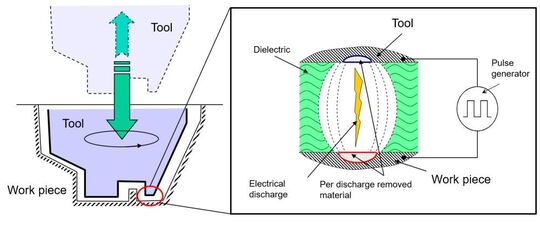

Electrical discharge machining EDM is one of the earliest non-traditional machining processes. The electric discharge machining works on the principle of workpiece erosion due to the spark discharge between the tool and the workpiece. EDM is an effective technique in the production of micro components that are smaller than 100µm.

Small Hole EDM Drilling Small hole EDM drilling also known as fast hole EDM drilling hole popper and start hole EDM drilling uses a. State-specific Legal Forms Form Packages for Other Services. Makino EDMs have a streamlined and efficient interface that helps work get done faster.

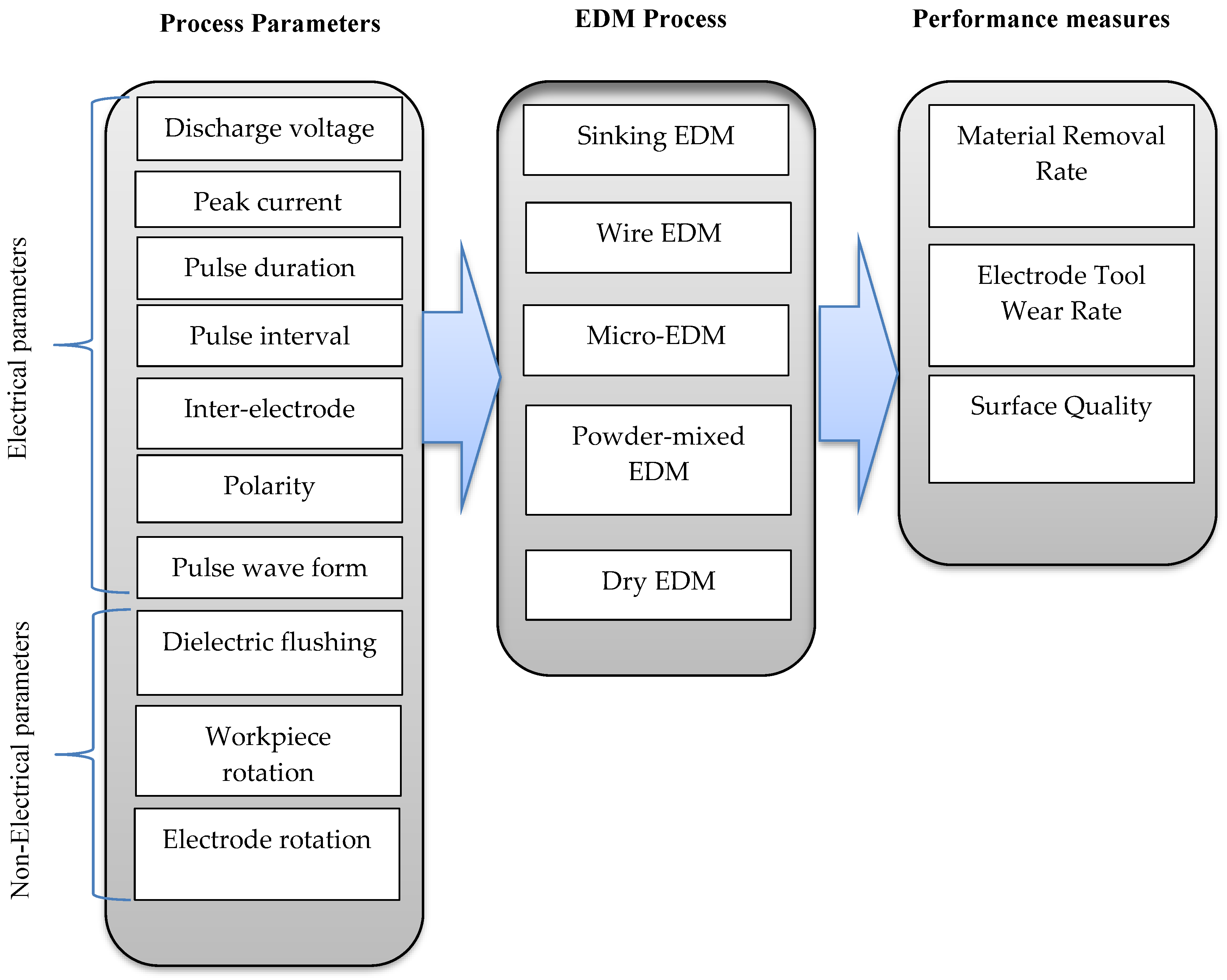

Here are some applications of Electrical Discharge Machining. The non-contact machining technique has been continuously evolving from a mere tool and die making process to a micro-scale application machining alternative attracting a significant. The process parameters that influence while electric discharge machining are listed below.

Electrical Discharge Machining was published by nttfdigitallibrary on 2017-12-02. Understanding Electrical Discharge Machining 25 C. Ad Sign Fill Out Legal Forms Online on Any Device.

Electrical discharge machining EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated. Discharge current - It points out the different levels of power that can be supplied by the. The finished object may be further refined by hard glass or soft paint enameling.

Electrical Discharge Machining EDM is a non-conventional machining process which is available from. Electrical Discharge Machining Fundamental Manufacturing Processes Video Series Study Guide - 2 - The finished EDMd workpiece can exhibit several distinct layers. Electrical discharge machine The traditional machining processes rely on harder tool or abrasive material to remove the softer material whereas non-traditional machining processes.

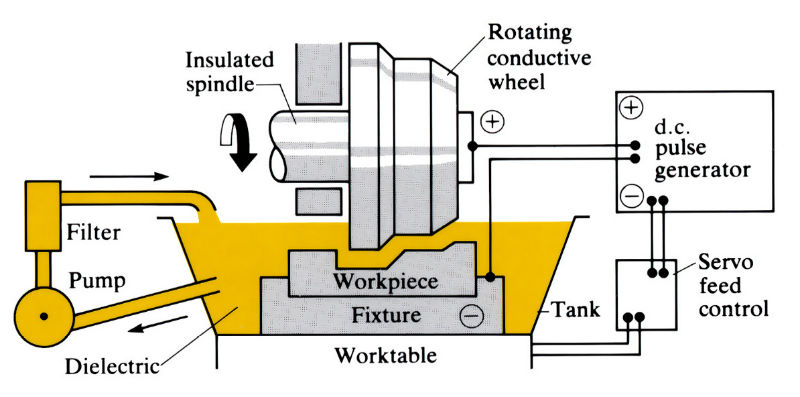

COINAGE DIE MAKING This type of EDM is usually performed submerged in an oil-based dielectric. Holes in the air brakes or. Dry Wire Electrical Discharge Machining of Thin Workpiece Research AssistantsStaff.

36 Be familiar with the location of emergency equipment - fire. Used for die sinking or die manufacturing. Material removal process has completed due to current.

Check Pages 1-50 of Electrical Discharge Machining in the flip PDF version. 2 electrodes namely the anode. EDM induces thermal stress in machined surfaces.

The surface layer will. BASICS OF ELECTRICAL DISCHARGE MACHINING The roots of electric discharge machining can be dated way back to 1770 after J. Ad Makino is the world leader in Electrical Discharge Machining.

Machining accuracy of the EDM is limited to about 0001 mm. INTRODUCTION Electric discharge machining EDM sometimes colloquially also referred to as spark machining spark eroding burning die sinking or wire erosion is a manufacturing. This is a manufacturing operation in which.

It is used for producing hole size less than 01 mm. Electrical Discharge Machining EDM is the process of machining electrically conductive materials by using precisely controlled sparks that occur between an electrode and a. Find Industry-specific Forms Now.

34 Always wear appropriate protective clothing. In the first stage there is removal of a toler- The effect of electrical-discharge machining parameters ance from a ceramic workpiece under action of electrical dis- on roughness Ra of. Minimum surface roughness average is about 01 m.

Electrical Discharge Machining An Overview Sciencedirect Topics

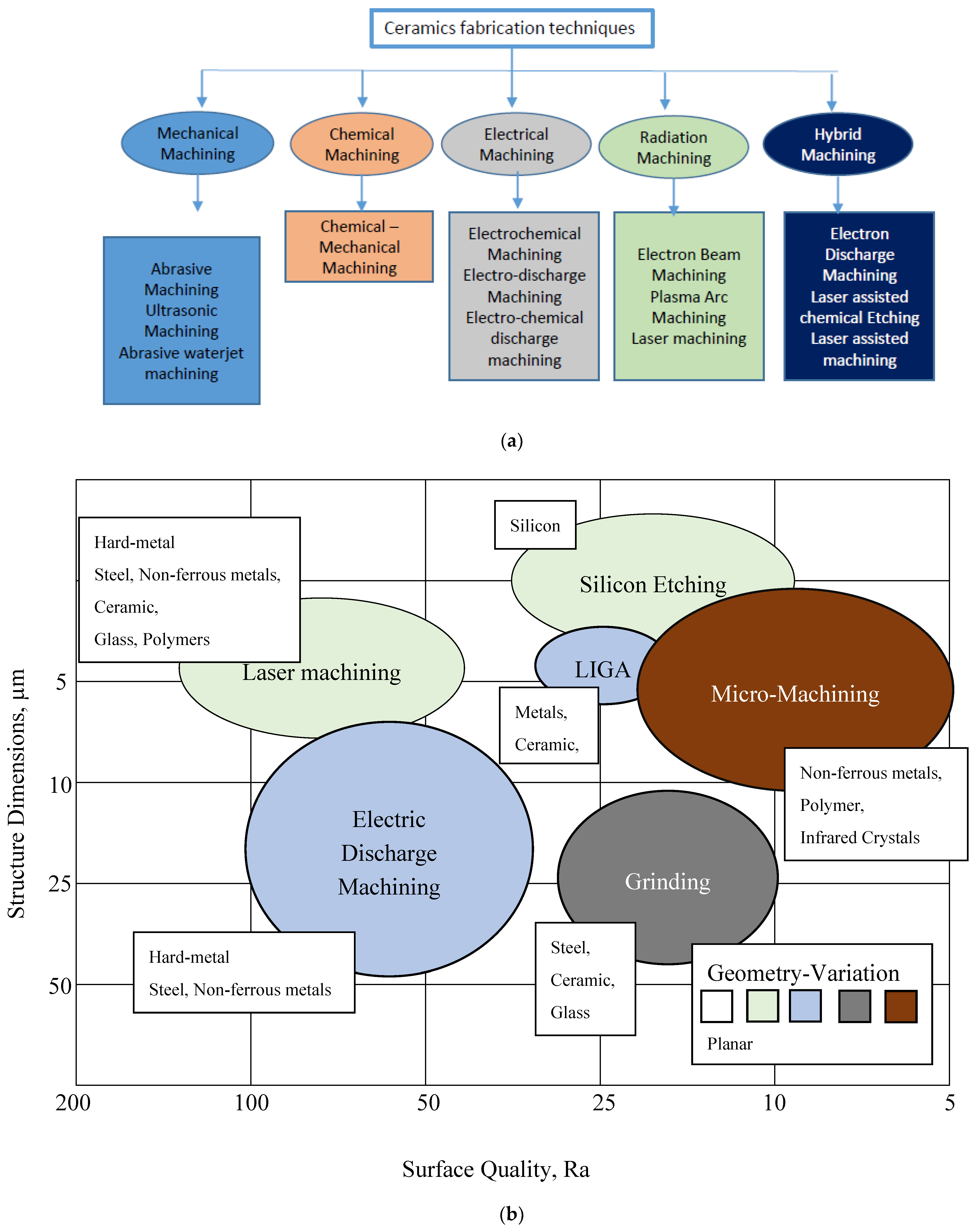

Micromachines Free Full Text Electro Discharge Machining Of Ceramics A Review Html

Materials Free Full Text Advanced Electric Discharge Machining Of Stainless Steels Assessment Of The State Of The Art Gaps And Future Prospect Html

Electrical Discharge Machining Edm Parts Working Principle Advantages Disadvantages Applications Pdf

Mas S62 Final Notes Bengineering

Electrical Discharge Machining Edm Parts Working Principle Advantages Disadvantages Applications Pdf

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University

Electro Discharge Machining Working Parts Advantage Application Pdf

Electrical Discharge Machining An Overview Sciencedirect Topics

Pdf Electrical Discharge Grinding Edg A Review Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

What Is Electrical Discharge Machining And How Does It Work

Pdf Electrical Discharge Grinding Edg A Review Semantic Scholar

Pdf Electrical Discharge Grinding Edg A Review Semantic Scholar

Pdf Electrical Discharge Grinding Edg A Review Semantic Scholar

Electric Discharge An Overview Sciencedirect Topics

Gate Ese Electrical Discharge Machining In Hindi Offered By Unacademy

Electrical Discharge Machining An Overview Sciencedirect Topics